Specification – Standard Vessels.

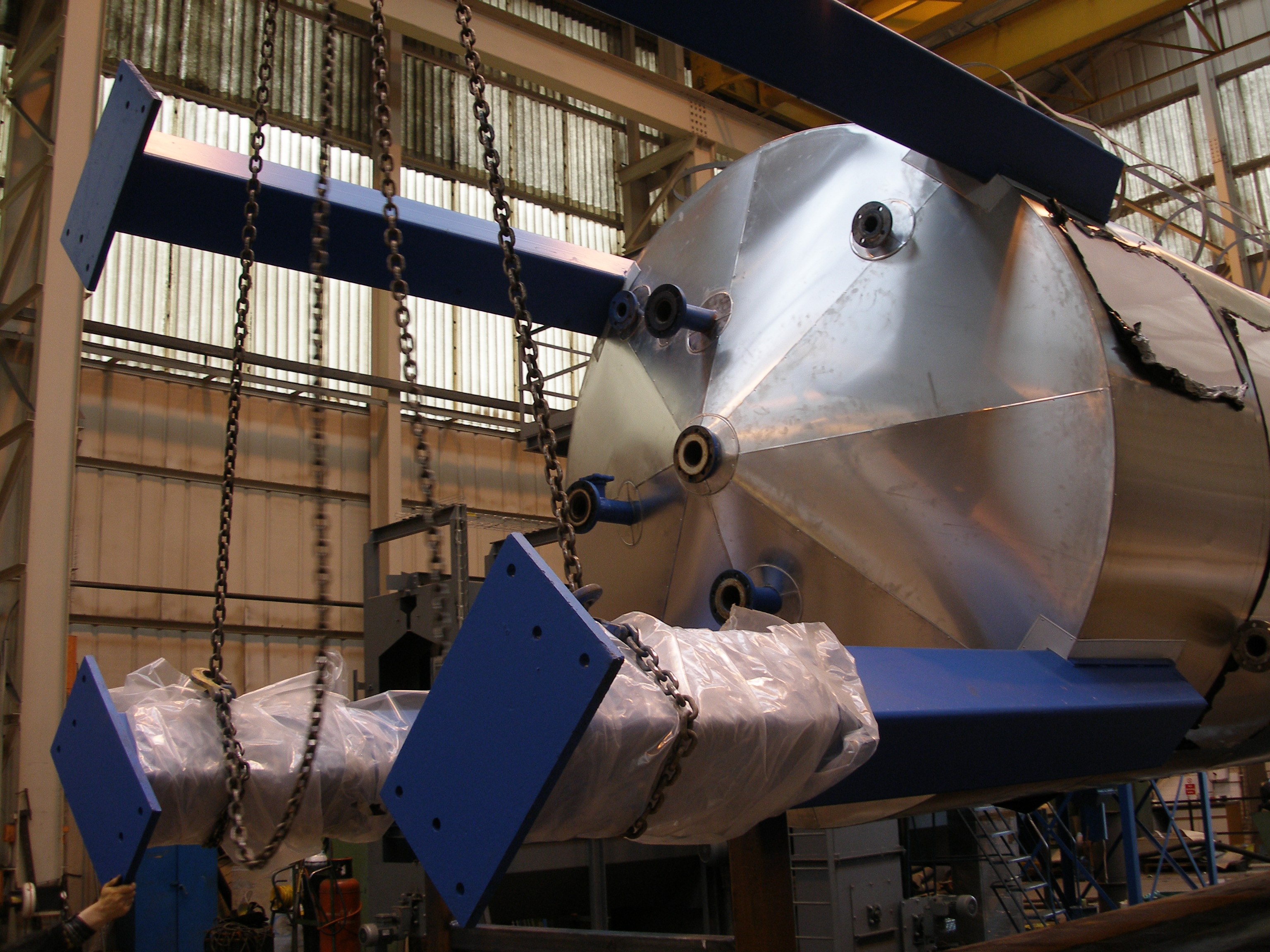

CONSTRUCTION Vertical cylindrical, leg mounted – Alternatively, horizontal cylindrical on two welded saddles.

DESIGN CODE BS5169:- PED Complaint Declaration of Conformity/Test Certificate supplied.

CAPACITY RANGE 250-9630 litres

PRESSURE RANGE 100 and 150 psi working pressure (8.3 and 11.0 Bar G)

STEEL GRADE EN10028-2 P265GH

TESTING As per design code.

FITTINGS 1– inlet socket or PN16 flange

- 1 – outlet socket or PN 16 flange

- 1,2 or 3 inspection opening’s

- 1 – relief valve socket

- 1 – pressure gauge socket

- 1 – drain valve socket

- 3 or 4 rolled steel angle legs, or two welded saddles

FINISH – Internal Self colour

FINISH – External As per Client requirements.

NON STANDARD AIR RECEIVERS

Air receivers of smaller, larger of intermediate capacities or for high pressures can be supplied and will be quoted on request.

|

NOMINAL

CAPACITY |

DIMENSIONS

|

INLET & OUTLET

|

INSPECTION OPENINGS

|

SUPPLY

LEGS |

||

|

DIAM

|

SHELL

|

O/A HT

|

||||

|

LITRES

|

‘A’

|

‘B’

|

‘C’

|

NB

|

No. x Size

|

No.

|

|

250

|

457

|

1500

|

2000

|

1″BSP

|

2-2″ BSP

|

3

|

|

340

|

508

|

1500

|

2030

|

1 1/2″ BSP

|

2-2″ BSP

|

3

|

|

500

|

610

|

1500

|

2070

|

2″ BSP

|

2-2″ BSP

|

3

|

|

875

|

762

|

1700

|

2270

|

2″ BSP

|

2-H/HOLES

|

3

|

|

1000

|

762

|

2000

|

2570

|

2″ BSP

|

2-H/HOLES

|

3

|

|

1250

|

900

|

1700

|

2300

|

65 NB

|

2-H/HOLES

|

3

|

|

1500

|

900

|

2000

|

2600

|

65 NB

|

2-H/HOLES

|

3

|

|

2000

|

1067

|

2000

|

2725

|

100 NB

|

2-H/HOLES

|

4

|

|

2720

|

1220

|

2000

|

2750

|

100 NB

|

2-H/HOLES

|

4

|

|

3320

|

1220

|

2500

|

3250

|

100 NB

|

2-H/HOLES

|

4

|

|

3880

|

1220

|

3000

|

3750

|

150 NB

|

2-H/HOLES

|

4

|

|

4490

|

1220

|

3500

|

4250

|

150 NB

|

3-H/HOLES

|

4

|

|

5080

|

1220

|

4000

|

4750

|

150 NB

|

3-H/HOLES

|

4

|

|

5660

|

1372

|

3500

|

4450

|

150 NB

|

1-420 x 320

|

4

|

|

7080

|

1525

|

3500

|

4500

|

150 NB

|

1-420 x 320

|

4

|

|

7930

|

1525

|

4000

|

5000

|

150 NB

|

1-420 x 320

|

4

|

|

9630

|

1676

|

4000

|

5050

|

150 NB

|

1-420 x 320

|

4

|