Specification – Standard Tanks.

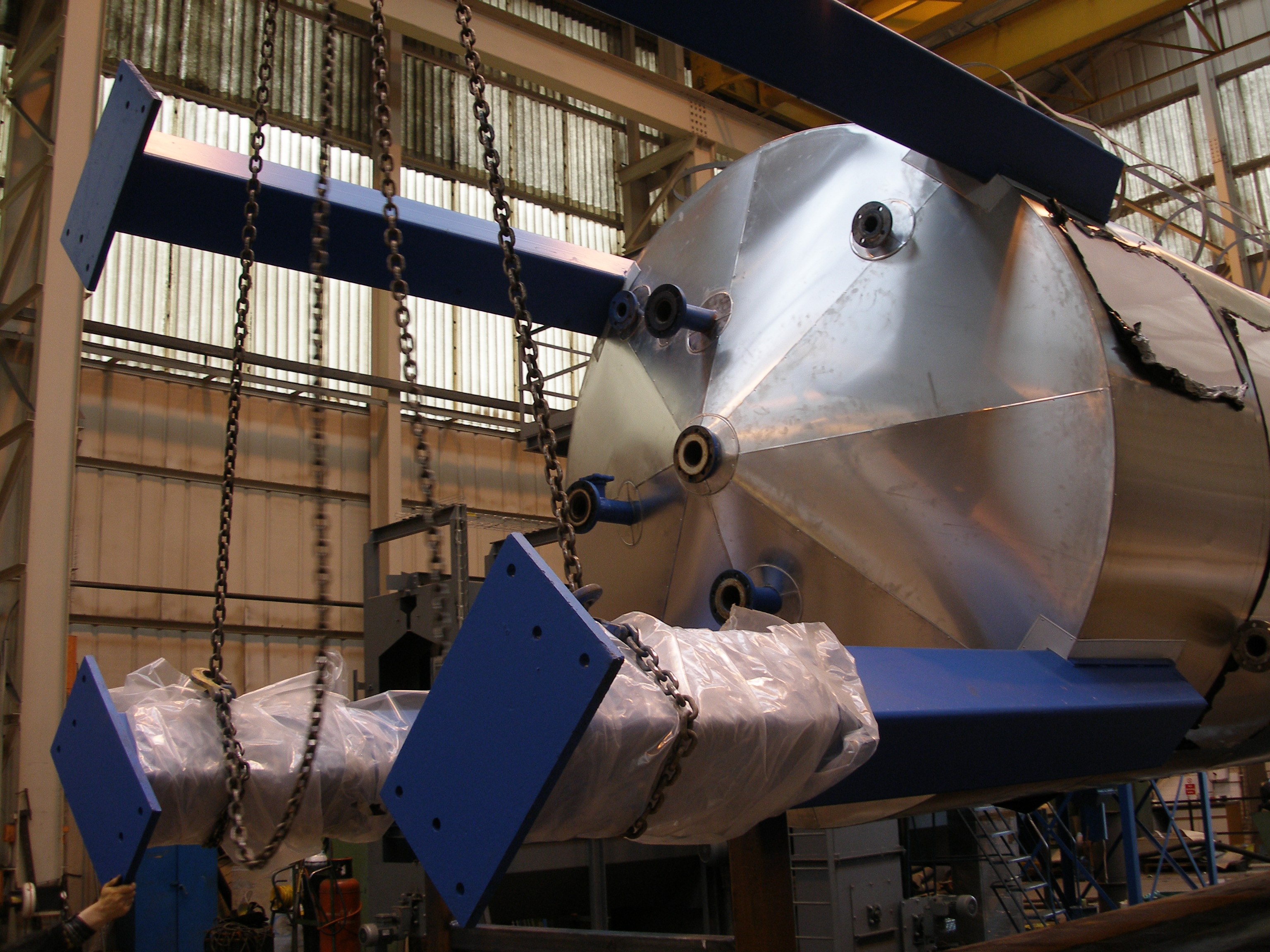

CONSTRUCTION Horizontal cylindrical, dished ends, of ‘twin skin’ design

DESIGN CODE BS EN 12285-1

CAPACITY RANGE As per Client requirements, for a rough guide of sizes please refer to table below.

STEEL GRADE BS EN 10025 S275JR

STEEL THICKNESS Inner tank shell 6mm shell, dished ends 6/8mm

Outer tank 4 mm shell, 5 mm dished ends

TESTING As per design code

STANDARD FITTINGS-(Guide Only) 1 – 600 dia shell manway, cover and gasket

- 1 – 100 BSP fill socket

- 1 – 50 BSP vent socket

- 1 – 80 BSP gauge/dip socket

- 3 – 50 NB suction/spare flanges

CAVITY MEDIUM Glycol/water mixture filled at works

FINISH -Internal Self colour, cleaned out

FINISH-External As per Client requirements

OPTIONAL EXTRAS

H.D. Straps, graduated diprods, access shaft, contents gauge, suction and sludge pipes, leak detection system, overfill prevention alarm, special internal/external paint finishes.

Below Ground Tanks – Single “Skin” Construction.

A COMPLEMENTING RANGE OF UNDERGROUND TANKS IS AVAILABLE WHERE EXTRA INTEGRITY AND SPILL PROTECTION WITH INBUILT LEAK DETECTION IS ESSENTIAL REFER TO LIST 13 FOR TWIN SKIN UNDERGROUND TANKS.

|

CAPACITY

|

DIMENSIONS

|

||||

|

NOMINAL

|

ACTUAL

|

DIAM

|

SHELL

|

O/AL

|

|

| Litres | M3 | M3 | MM | MM | MM |

| 2300 | 2.3 | 2.2 | 1372 | 1500 | 1740 |

| 4500 | 4.5 | 4.5 | 1372 | 3050 | 3290 |

| 6900 | 6.9 | 7.3 | 1525 | 3660 | 3940 |

| 9100 | 9.1 | 9.4 | 1830 | 3355 | 3695 |

| 13600 | 13.6 | 14.1 | 2135 | 3680 | 4060 |

| 19000 | 19.0 | 18.8 | 2287 | 4375 | 4680 |

| 23200 | 23.2 | 22.8 | 2287 | 5520 | 5900 |

| 27700 | 27.7 | 28.1 | 2440 | 5795 | 6255 |

| 31800 | 31.8 | 32.2 | 2745 | 5205 | 5745 |

| 36500 | 36.5 | 36.1 | 2745 | 6000 | 6540 |

| 40500 | 40.5 | 41.7 | 2745 | 6730 | 7270 |

| 45400 | 45.4 | 45.1 | 2745 | 7500 | 8040 |

| 55100 | 55.1 | 54.1 | 2745 | 9150 | 9690 |