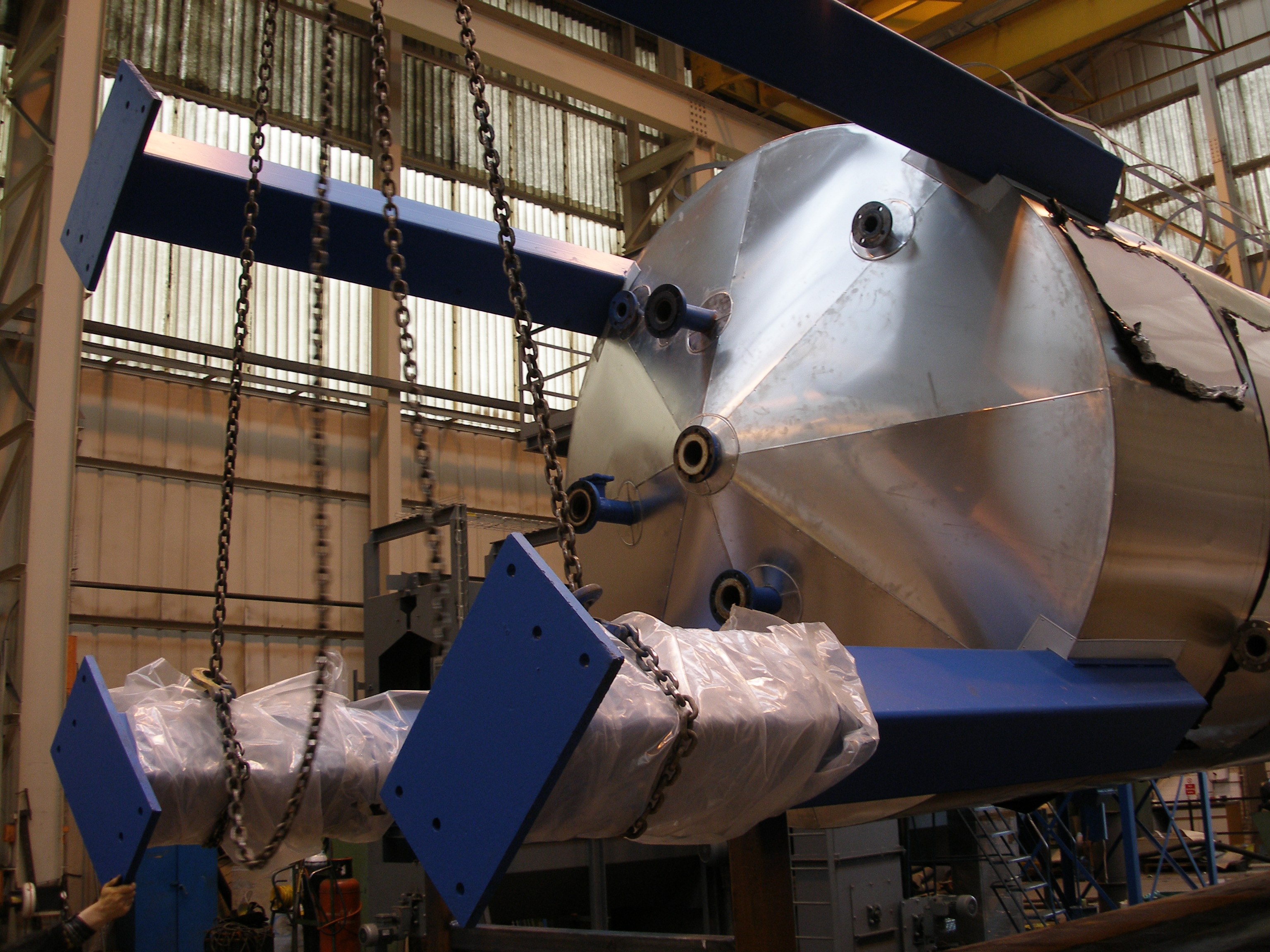

Specification – Standard Tanks – ‘Plate Small’ Supply.

Site erect & install by others.

CONSTRUCTION Vertical cylindrical, flat base,fixed cone roof

DESIGN CODE Generally to BSEN14015

CAPACITY RANGE 50 – 11700 tonne (50000 – 11.75 million litres)

TEMPERATURE RANGE -10 degC +150 degC

SPECIFIC GRAVITY 1.0 Maximum

PRESSURE RATING 10 millibar pressure/5 millibar vacuum

ROOF DESIGN Fixed cone, 1 in 5 slope. Self supporting. Roof plates welded topside only

BASE DESIGN Lap welded top side only. Tanks above 12.5M diam have annular plate ring

SHELL DESIGN Butt welded, internal and external, with top curb ring

WIND GIRDERS RSA, as required by code.

STEEL GRADE BSEN 10025 S275JR

INSPECTION All tank components inspected at works for dimensional and material conformity, surface preparation and treatment, packed to specification agreed.

FINISH Base plates Heavy bitumen on underside

External Self colour / Intemal Self colour

DRAWINGS/DOCUMENTS Full drawings and assembly instructions for site erection by others.

PACKING FOR SHIPMENT Rolled shell plates packed in purpose made non returnable transit cradles, securely strapped. Max 10000 Kg.

Tank base and roof plates,structural sections with welded straps.

Max 6000 Kg. Loose fittings, electrodes, etc. close board cased.

|

DIMENSIONS

|

NOMINAL

CAPACITY

|

|

DIAM

|

HEIGHT

|

|

M

|

M

|

M3

|

|

4

|

4

|

50

|

|

6

|

75

|

|

8

|

100

|

|

10

|

125

|

|

5

|

6

|

117

|

|

8

|

157

|

|

10

|

196

|

|

6

|

6

|

169

|

|

8

|

226

|

|

10

|

282

|

|

8

|

6

|

301

|

|

8

|

402

|

|

10

|

502

|

|

12

|

602

|

|

10

|

8

|

628

|

|

10

|

785

|

|

12

|

942

|

|

14

|

1099

|

|

12.5

|

10

|

1227

|

|

12

|

1472

|

|

14

|

1718

|

|

16

|

1963

|

|

15

|

12

|

2120

|

|

14

|

2474

|

|

16

|

2828

|

|

17.5

|

14

|

3365

|

|

16

|

3846

|

|

18

|

4325

|

|

20

|

16

|

5026

|

|

18

|

5654

|

|

20

|

6282

|

|

22.5

|

18

|

7156

|

|

20

|

7951

|

|

22

|

8746

|

|

25

|

20

|

9816

|

|

22

|

10707

|

|

24

|

11799

|