Specification – Standard Tanks.

CONSTRUCTION Rectangular stiffened, with integral bund of 110% + capacity

DESIGN CODE Tank to BS799 Pt 5:type ‘J’

STEEL GRADE BSEN 10025 S275JR

TESTING As per design code.

STANDARD FITTINGS (Guide only) 1 – 600 dia access manhole with bolted cover

- 1 – 65NB offset fill pipe with valve and cap

- 1 – 65NB cowled vent

- 1 – 65NB vent link pipe

- 1 – 40NB feed pipe with valves

- 2 – 20NB tank and bund drain valves

- 1 – Leak detection sight glass

- 2/4 – Empty tank lifting lugs

FINISH – Internal Self colour, cleaned out

FINISH – External As per Client requirements.

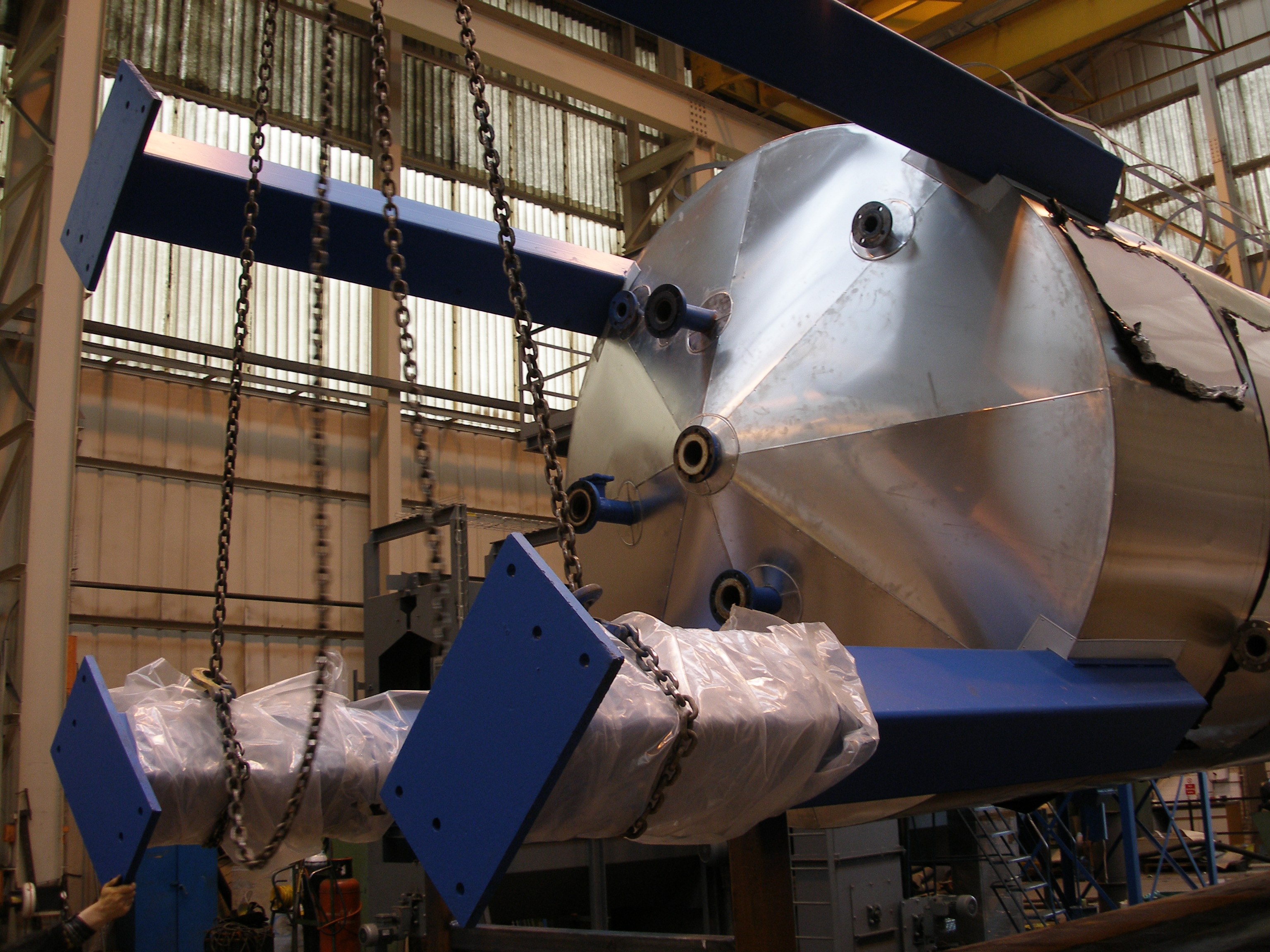

SUITABILITY – DOUBLE SKIN BUNDED TANKS

Although designed primarily for fuel (gas oil, derv) storage, tanks with integral bunds are equally suited to storage of many other liquids. Special duty double skin bunded tanks can be designed, Horizontal or vertical cylindrical, with special internal linings if product stored is corrosive, or can be fabricated in stainless steel.

|

NOMINAL CAPACITY

|

NOMINAL OVERALL DIMENSIONS

|

||

|

LENGTH

|

WIDTH

|

HEIGHT

|

|

|

LITRES

|

MM

|

MM

|

MM

|

|

2300

|

1930

|

1320

|

1220

|

|

4500

|

2540

|

1625

|

1220

|

|

6800

|

3150

|

1600

|

1500

|

|

9100

|

4200

|

1650

|

1500

|

|

11300

|

4300

|

1650

|

1830

|

|

13600

|

5150

|

1650

|

1830

|

|

18200

|

5500

|

1980

|

1830

|

|

22700

|

5850

|

2150

|

2000

|

|

27200

|

6400

|

2640

|

1830

|

|

31800

|

7400

|

2640

|

1830

|

|

36400

|

7650

|

2640

|

2000

|

|

40900

|

7100

|

3200

|

2000

|

|

45500

|

7800

|

3200

|

2000

|

|

54500

|

9350

|

3200

|

2000

|

|

68200

|

9600

|

3200

|

2440

|

|

90900

|

10200

|

3250

|

3000

|