Project: Alexion Pharma Energy Centre, Dublin September 2016

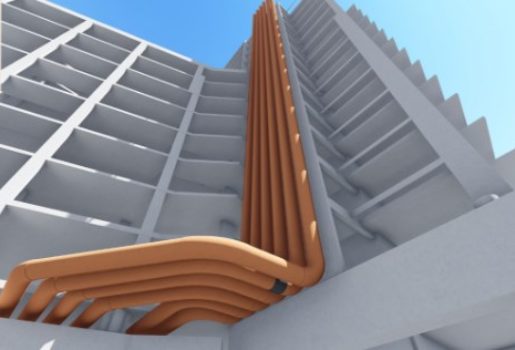

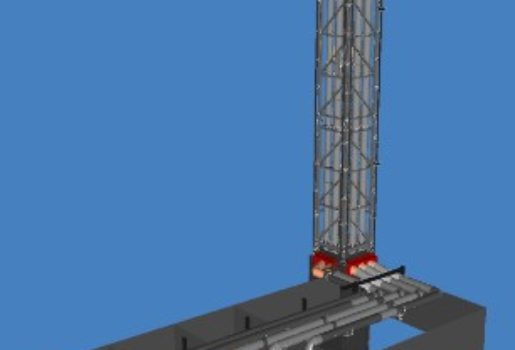

Cochran Ltd contracted HM to design, fabricate and install a 50M structural mast to support 4 off 700mm ID stainless boiler flu liners and 1 off high temp CHP 550mm liner. In addition to this we also fabricated and erected up to 170M of fully welded horizontal stainless duct and made connections back to the boilers and CHP.

The mast was built in accordance with design criteria EN 1993-1-1:2005. The fabrication was in line with EN1090-3 for which HM have recently received full accreditation.

The mast was a challenging 4.6M2 square in plan and was fabricated in 4 off 12M sections. Head height clearance on the ferry was a comfortable 50mm from the roof!

Each section was built to maximise cross sectional space within the mast between the vertical liners. However our designers were always challenged with ensuring that the masts remained transportable overseas.

The complete install took was carried out by a 5 man team and took just 3 days from start to finish. Once erected the horizontal duct was then lifted on to the roof and connected once the mast sections had been fully cladded.

The horizontal duct inside the Energy centre was installed at 10M height and special expansion joints were installed by HM to accommodate the expansion over the long lengths from boiler to stack. On completion all the duct was clad insitu.