Specification – Standard Tanks.

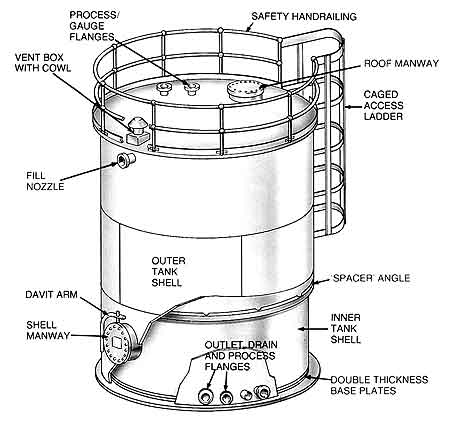

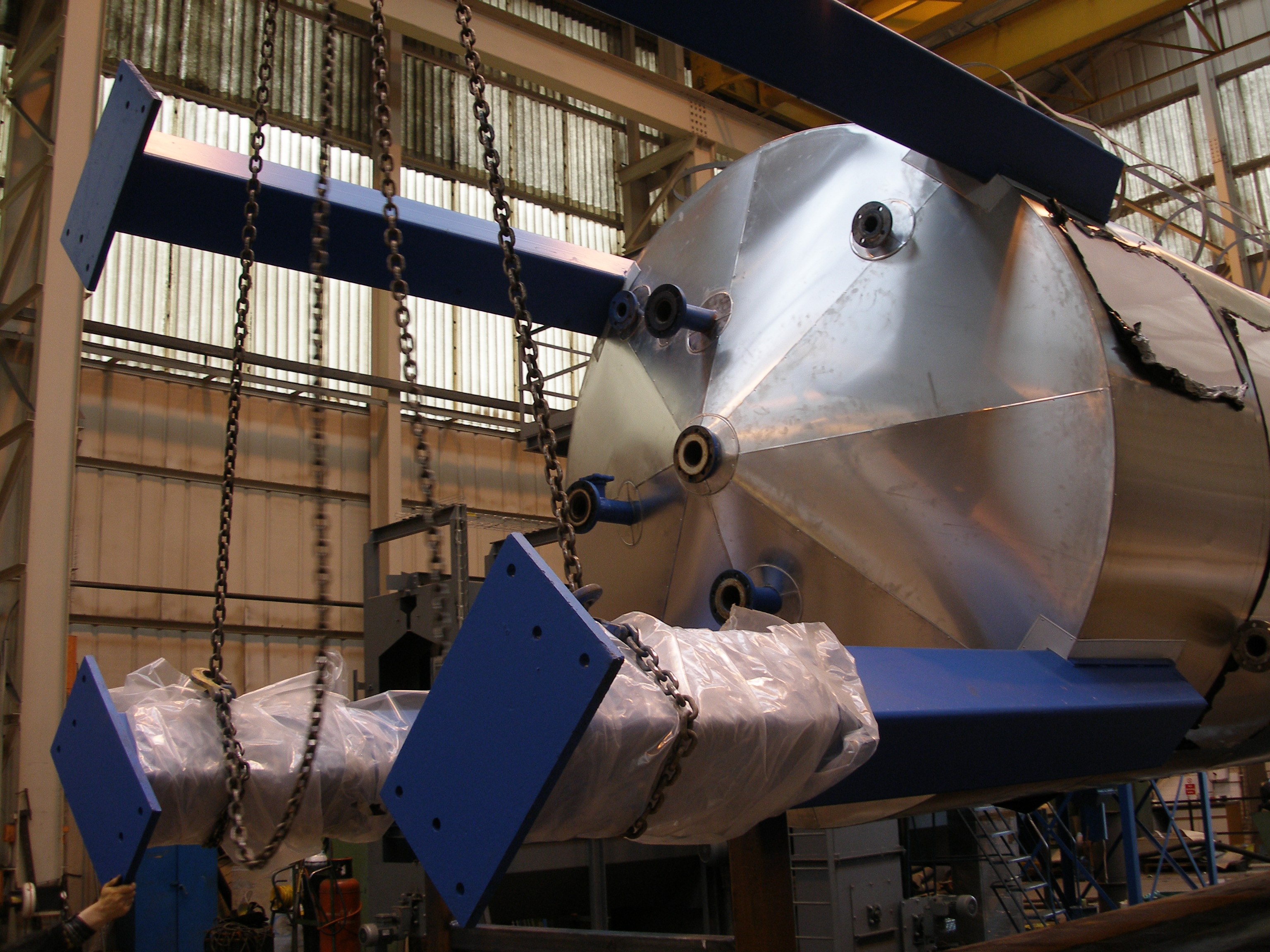

CONSTRUCTION Vertical cylindrical double shell and base plates, single skin roof, site welded

SPILLAGE VOLUME 110% (min) of gross product volume

DESIGN CODE Generally to BSEN14015

CAPACITY RANGE 150-1000 cubic metres

STEEL GRADE BSEN 10025 S275JR

TESTING – Inner Air. Hydrostatic and radiography at extra cost

– Outer Air test

FITTINGS As per Client requirements.

FINISH – Internal Self colour, cleaned out

FINISH – External As per Client requirements.

OPTIONAL FEATURES Heating coils, insulation, gauges, switches, overfill alarm, special linings and coatings, interconnecting walkways

ADVANTAGES OF ‘TWIN SKIN’ TANKS

With growing demand for environmental protection, advantages of Hartwell ‘Twin Skin’ double integrity fuel oil and chemical storage tanks are increasingly recognised. Open spillage bunds present hazards and drainage problems, eliminated entirely by containing spilled fuels and noxious liquids inside their own integral bund compartments. Significant open bund space and civil cost savings can be achieved.

|

NOMINAL

CAPACITY |

ACTUAL GROSS

CAPACITY |

DIMENSIONS

|

||

|

DIAMETER

|

SHELL

HEIGHT |

|||

|

INNER

|

OUTER

|

|||

|

M3

|

M3

|

M

|

M

|

M

|

|

150

|

157.1

|

5.0

|

5.3

|

8.0

|

|

175

|

176.7

|

5.0

|

5.3

|

9.0

|

|

200

|

197.9

|

6.0

|

6.4

|

7.0

|

|

300

|

296.9

|

6.0

|

6.4

|

10.5

|

|

400

|

402.1

|

8.0

|

8.4

|

8.0

|

|

500

|

502.7

|

8.0

|

8.4

|

10.0

|

|

600

|

603.2

|

8.0

|

8.4

|

12.0

|

|

700

|

706.9

|

10.0

|

10.5

|

9.0

|

|

800

|

824.7

|

10.0

|

10.5

|

10.5

|

|

900

|

903.3

|

10.0

|

10.5

|

11.5

|

|

1000

|

1021.1

|

10.0

|

10.5

|

13.0

|