Specification.

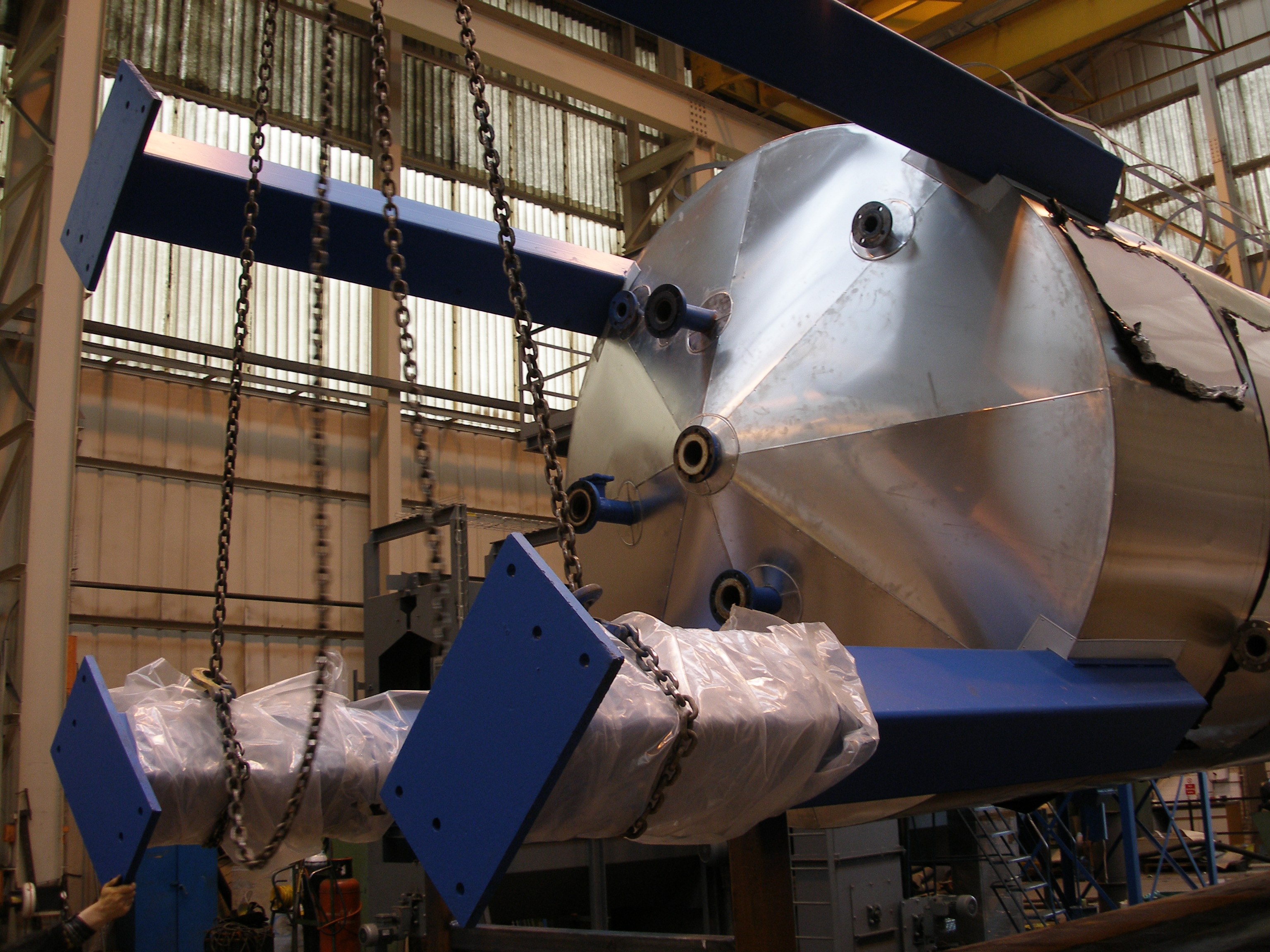

CONSTRUCTION Horizontal cylindrical, flat stiffened ends, mounted on fully welded saddles

CAPACITY RANGE 30-100 cubic metres

DESIGN CODE Good Engineering Practice and generally to EN12285-2

STEEL CODE BS EN 10025 S275JR

TESTING 0.07 barG air

FITTINGS (Guide only) 1 – 600 dia top manway with Iockable cover. 4 – 80 NB fill, outlet, return and drain flanges. 1 – 100 NB vent/overflow flange. 1 – 50 NB contents indicator flange

LIFTING LUGS 2 – Welded shell lugs

INSULATION 150mm thick 45kg/M3 ‘Rockwool’ with 0.7mm thick aluminium or galvanised cladding on all hot surfaces.

FINISH – Internal Self colour cleaned out

FINISH – External As per Client requirements.

OPTIONAL ACCESSORIES Galvanised access ladder / Top platform with handrailing / Calibrated contents gauge / 80 NB fill pipe assembly, with hand valve / Galvanised access ladder / Top platform with handrailing / Calibrated contents gauge / 80 NB fill pipe assembly, with hand valve

HEATING OPTIONS Thermal oil, electric or direct fired